Courtesy of Daniel Ortegon, architectural drafter.

It's very thrilling to see my future house framed in 3-D. So far my visual representation ability has been somewhat limited to 2-D (aside from a paper model I made of my previous design. That was a very good exercise which I highly recommend, suggested to me by an achitect friend.)

It still needs window and chimney openings, will post again with updated drawing. Anyhoo, check this beauty out:

Awesome! Fun to visualise this becoming a real-life structure.

Thursday, September 4, 2014

Monday, August 25, 2014

New Design??!

Woah! Changing horses mid-stream... good thing this stream ain't flowin' that fast. Har.

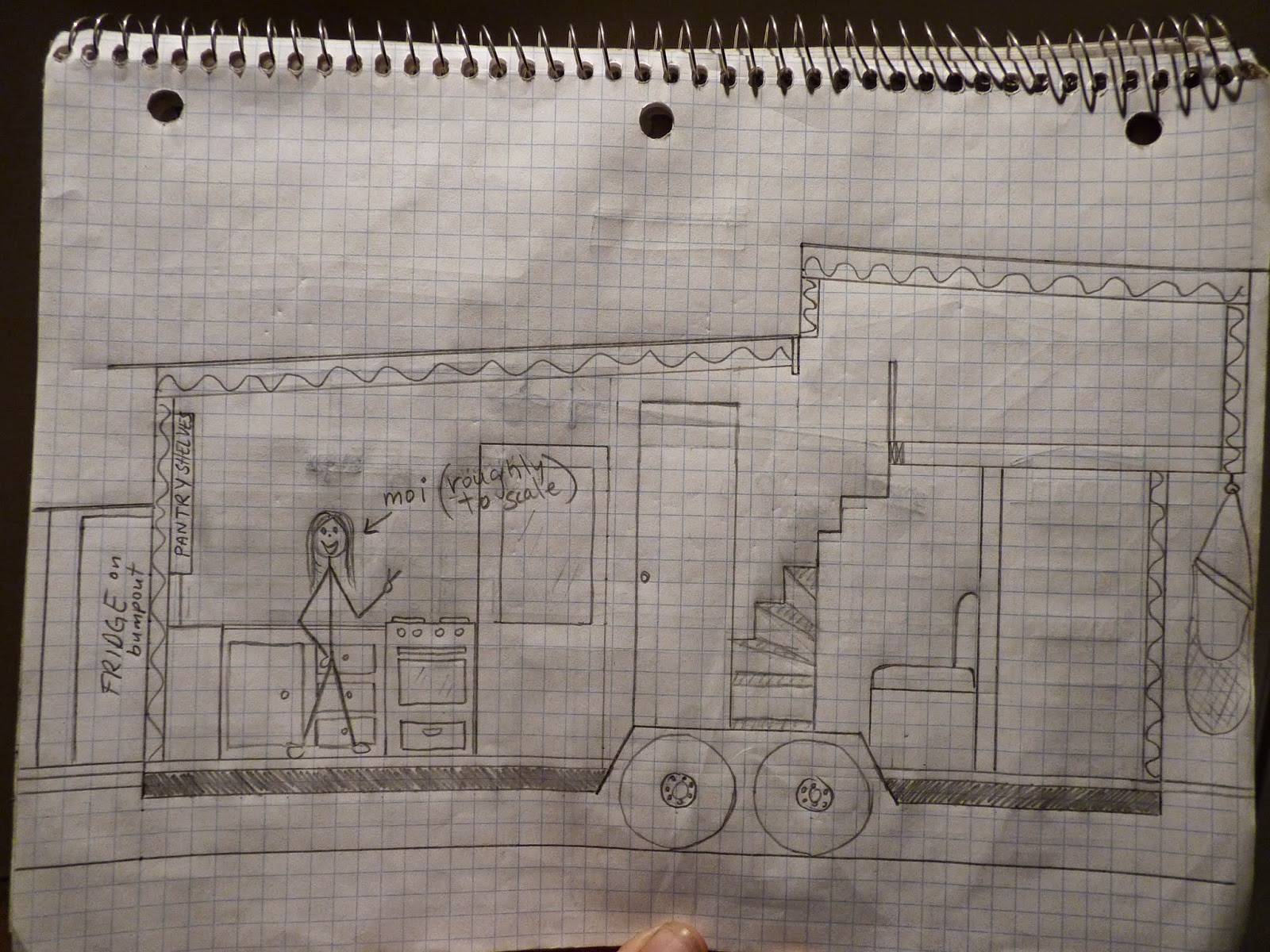

Upon further consideration, I'm now considering... a different roof! Here's my relatively unchanged floorplan:

And a updated profile drawing, with shed roof:

This roof design is heavily inspired by Brett Sutherland from New Zealand's little house: https://www.youtube.com/watch?v=VckbqU4kK2I.

The idea to change is based upon the thinking that my previous roof design (gambrel roof, with low pitch gable roof over loft) is likely heavier, and more complicated to build. Simpler and lighter is just too tempting to pass up. Plus I quite like the modern look this roof gives. Cool house Brett!

Any thoughts are welcome! Thanks!

And yes, that's a hammock hanging from the back of the house :-)

Upon further consideration, I'm now considering... a different roof! Here's my relatively unchanged floorplan:

And a updated profile drawing, with shed roof:

This roof design is heavily inspired by Brett Sutherland from New Zealand's little house: https://www.youtube.com/watch?v=VckbqU4kK2I.

The idea to change is based upon the thinking that my previous roof design (gambrel roof, with low pitch gable roof over loft) is likely heavier, and more complicated to build. Simpler and lighter is just too tempting to pass up. Plus I quite like the modern look this roof gives. Cool house Brett!

Any thoughts are welcome! Thanks!

And yes, that's a hammock hanging from the back of the house :-)

Sunday, August 17, 2014

Insulation station

|

| floor foam |

I'm insulating the floor now, which is pretty exciting. Mostly in that it's not screwing metal onto other metal. I've been doing a lot of that up till now :-)

Relative to that, insulation is a piece of cake! (More on the cake part later...)

I have to fill a 5" cavity, which is an odd dimention. So, mix n' match. Bottom layer, rigid foam. On top of that, Roxul. Both seem to do okay with moisture, which is why I chose them for the floor. Couldn't get the straight answer on if Roxul contains formaldehyde... I'm keeping it confined to the floor, where it will be fairly well sealed in.

| ||||||||||||

| caulking |

|

| patches for holes in flashing |

|

| roxul |

And, for good measure, some more metal screwed to metal. This is the front edge of the trailer, where the flashing and frame meet. Butyl caulk in between, and screwed.

And, for good measure, some more metal screwed to metal. This is the front edge of the trailer, where the flashing and frame meet. Butyl caulk in between, and screwed.  |

| Insucake! |

It's so easy to cut this stuff, and it makes me imagine that I'm cutting a big sponge cake.

Ultra effective and stylish safety gear

|

| bandita de Roxul |

|

| sound system |

Monday, July 7, 2014

More cutting, screwing and hanging out under my trailer

My flashing is more or less installed now, which gives the trailer a much different look!

Here I am cutting the sheet metal with electric shears:

It makes fun curly strips of metal!

Bird's eye view of the trailer with flashing and boards attached to the metal joists

View of the underside of the flashing. The 1" screws go into the bottoms of the 2x5" boards, which are isolated from the metal by a strip of sill gasket. I will seal the seams with butyl cocking and screws on the overlapping sections (there is a 2" to 4" overlap on all seams)

Here you can see the depth of the floor cavity, the bolts and screws attaching the boards to the metal joists, the strip of sill gasket, and the flashing under it all.

Next up: insulation! I decided on a 1 1/2" layer of durafoam to go on top of the metal, then fill in the rest of the cavity with 3 1/2" of Roxul. Then I will put a layer of 1" durafoam on top of the whole platform, to isolate the metal joists from the plywood floor decking.

After that... framing. Oh sweet, sweet framing to take me into the realm of the vertical... I so need to go vertical, all this horizontal is getting me down :-D

hehe

Here I am cutting the sheet metal with electric shears:

It makes fun curly strips of metal!

Bird's eye view of the trailer with flashing and boards attached to the metal joists

View of the underside of the flashing. The 1" screws go into the bottoms of the 2x5" boards, which are isolated from the metal by a strip of sill gasket. I will seal the seams with butyl cocking and screws on the overlapping sections (there is a 2" to 4" overlap on all seams)

Here you can see the depth of the floor cavity, the bolts and screws attaching the boards to the metal joists, the strip of sill gasket, and the flashing under it all.

Next up: insulation! I decided on a 1 1/2" layer of durafoam to go on top of the metal, then fill in the rest of the cavity with 3 1/2" of Roxul. Then I will put a layer of 1" durafoam on top of the whole platform, to isolate the metal joists from the plywood floor decking.

After that... framing. Oh sweet, sweet framing to take me into the realm of the vertical... I so need to go vertical, all this horizontal is getting me down :-D

hehe

Tuesday, June 24, 2014

Two steps back equals four steps forward!

Ok, since my last post I've had to do a bit of backtracking. That's not super fun, cause it feels like taking steps back instead of moving forward on the project. But in reality I have been moving forward as the extra steps will be worth it in the long run.

My framer suggested that the bare wood against metal might be prone to rotting over time from condensation on the metal, so I've taken some steps to protect it. I took all of the 2x5s off and covered them with two coats of high quality exterior grade primer. I also attached strips of sill gasket to the wood where it will be in contact with the metal of the trailer frame and with the metal flashing underneath.

He also suggested that attaching the boards to the trailer with screws alone would not be strong enough over time, what with some vibration from moving the trailer. Even though the boards won't be load bearing, they need to be securely fastened. So I took them off, drilled the existing holes in the boards to accomodate 14" bolts, drilled corresponding holes right through the trailer joists, and have transferred the screws that were in there to the middle of the boards. They're all back on now, and looking snazzy. Just like this guy:

What an awesome helper. Thanks Carl!

Oh, that metal beam is clamped on there to keep the wood boards from crowing up abover the level of the metal joists while Carl screwed them back on.

Now I'm back to attaching the flashing to the bottom. The first sheet is on, and the second one's ready to go on now too, with cuts made for where the tongue attaches to the main frame.

Feels like I'm moving forward again... :-)

My framer suggested that the bare wood against metal might be prone to rotting over time from condensation on the metal, so I've taken some steps to protect it. I took all of the 2x5s off and covered them with two coats of high quality exterior grade primer. I also attached strips of sill gasket to the wood where it will be in contact with the metal of the trailer frame and with the metal flashing underneath.

He also suggested that attaching the boards to the trailer with screws alone would not be strong enough over time, what with some vibration from moving the trailer. Even though the boards won't be load bearing, they need to be securely fastened. So I took them off, drilled the existing holes in the boards to accomodate 14" bolts, drilled corresponding holes right through the trailer joists, and have transferred the screws that were in there to the middle of the boards. They're all back on now, and looking snazzy. Just like this guy:

What an awesome helper. Thanks Carl!

Oh, that metal beam is clamped on there to keep the wood boards from crowing up abover the level of the metal joists while Carl screwed them back on.

Now I'm back to attaching the flashing to the bottom. The first sheet is on, and the second one's ready to go on now too, with cuts made for where the tongue attaches to the main frame.

Feels like I'm moving forward again... :-)

Monday, June 9, 2014

Things is happening

This past week I've made PROGRESS! Since the last post:

I've nearly finished attaching all of the flashing supports to the steel joists:

Now I'm getting ready to attach the flashing to the underside of the trailer. First, measuring!

I cut a cardboard jig for a couple of the cuts I need to make in the metal:

Did some drawing to figure out placement of the metal sheets under the trailer:

And made a couple of cuts. It's not as hard to cut sheet metal as I thought it would be. Not to say that my cuts are really pretty, I'm sure it's trickier to do it nicely. But mine don't need to be pretty :-) This one's not using the jig, but rather from measurements and the drawings I made.

Here's the metal wedged up under the frame. It took two of us to jam it in to the two cuts near the corner (bottom left, near my foot) There was just enough flexibility in the metal the bend it into place.

I've used some long pieces of 1x6 suspended from the trailer frame to form a platform to hold the metal up where it needs to be. There are also a couple of long pieces of metal bar running the length of the sheet to keep it straight and flat. The sheets were a bit curvy, but working them with hands and feet straightened them out a bit.

Finally, here's a sample of the tools I've been using the past couple of days. Not included are the chop and table saw, and a few other little mecanically helpful friends.

Woop!

I've nearly finished attaching all of the flashing supports to the steel joists:

I cut a cardboard jig for a couple of the cuts I need to make in the metal:

Did some drawing to figure out placement of the metal sheets under the trailer:

And made a couple of cuts. It's not as hard to cut sheet metal as I thought it would be. Not to say that my cuts are really pretty, I'm sure it's trickier to do it nicely. But mine don't need to be pretty :-) This one's not using the jig, but rather from measurements and the drawings I made.

Here's the metal wedged up under the frame. It took two of us to jam it in to the two cuts near the corner (bottom left, near my foot) There was just enough flexibility in the metal the bend it into place.

I've used some long pieces of 1x6 suspended from the trailer frame to form a platform to hold the metal up where it needs to be. There are also a couple of long pieces of metal bar running the length of the sheet to keep it straight and flat. The sheets were a bit curvy, but working them with hands and feet straightened them out a bit.

Finally, here's a sample of the tools I've been using the past couple of days. Not included are the chop and table saw, and a few other little mecanically helpful friends.

Woop!

Sunday, June 8, 2014

drilling into metal is not so easy

I'm working on attaching the trailer flashing to the trailer. I got sheets of 4'x10' galvanized steel off c-list, really good price. Hoping that they will be a thick enough gauge. I had to pressure wash them first as they were quite filthy. Before:

And after:

To begin with I have to attach something to bring the level of the joists down to 5 inches (they are only 2 1/2). So I'm attaching 6' lengths of 2x6s that I've ripped to 5". Here's what it looks like:

Next up is puzzle piecing the metal sheets together so that they overlap properly and all end up resting on joists.

Onward!

And after:

To begin with I have to attach something to bring the level of the joists down to 5 inches (they are only 2 1/2). So I'm attaching 6' lengths of 2x6s that I've ripped to 5". Here's what it looks like:

Next up is puzzle piecing the metal sheets together so that they overlap properly and all end up resting on joists.

Onward!

Wednesday, May 7, 2014

first post! I have a trailer!

Hi,

thanks for checking out my blog about the little house I'm building. It's just getting started, and it's pretty exciting. I don't like spending a lot of time writing about what's already happened, so unless I start getting really into it these posts are likely to be short. Perhaps sweet, sometimes. Hopefully I'll be able to keep up on it and include lots of photos. To begin with, here's a photo of me and my sexy new trailer:

What a beauty she is. Very well-crafted by the very friendly, helpful and professional team at The Trailerman in Abbotsford. Ted there spent hours consulting with me via phone and email on the specs for the custom trailer build. Here he is affixing the licence plate:

First vehicle I've ever has registered and insured in my name! I love the little plate.

Fun and busy times ahead!

thanks for checking out my blog about the little house I'm building. It's just getting started, and it's pretty exciting. I don't like spending a lot of time writing about what's already happened, so unless I start getting really into it these posts are likely to be short. Perhaps sweet, sometimes. Hopefully I'll be able to keep up on it and include lots of photos. To begin with, here's a photo of me and my sexy new trailer:

What a beauty she is. Very well-crafted by the very friendly, helpful and professional team at The Trailerman in Abbotsford. Ted there spent hours consulting with me via phone and email on the specs for the custom trailer build. Here he is affixing the licence plate:

First vehicle I've ever has registered and insured in my name! I love the little plate.

Fun and busy times ahead!

Subscribe to:

Posts (Atom)